Ferrite magnetic rings are cost-effective and durable magnets made primarily from iron oxide, featuring moderate magnetic strength and excellent resistance to corrosion.

Their stability under high temperatures and affordable production cost make them one of the most widely used magnetic materials worldwide.

Key Applications:

1. Electric motors and generators (e.g., ceiling fans): Widely used as permanent magnets due to their durability, temperature stability, and cost-efficiency.

2. Medical equipment and sensors: Provide consistent magnetic fields for certain medical devices and detection systems.

3. Outdoor and industrial projects: With strong resistance to heat and corrosion, ferrite rings are reliable for outdoor applications and harsh environments.

4. Everyday consumer products: Commonly used in refrigerator magnets, magnetic holders, and small appliances for simple and practical functionality.

Advantages:

High corrosion resistance (no need for additional coating in most cases)

Stable performance at elevated temperatures

Cost-effective compared with rare-earth magnets

Available in a wide range of sizes, with customization options for specific designs

Because of their balance of performance, durability, and affordability, ferrite magnetic rings remain a versatile choice for both industrial and consumer applications.

Neodymium Iron Boron (NdFeB) magnets, also known as Neo magnets, are the most powerful permanent magnets available today, offering

the highest energy product of any magnetic material. They can be manufactured in a wide range of shapes, sizes, and grades to meet diverse

application requirements.

Applications

NdFeB magnets are widely used in:

High-performance motors and brushless DC motors

Magnetic separation systems

Medical imaging equipment (MRI)

Precision sensors and switches

Loudspeakers and acoustic devices

Performance & Advantages

Exceptional magnetic strength relative to their size and weight

Versatility in design, as magnetic properties can be tailored by alignment direction during compaction and by adjusting shape and size

High efficiency, making them ideal for modern compact and energy-saving technologies

Limitations & Solutions

As NdFeB magnets are prone to corrosion, a protective coating is strongly recommended. Common surface treatments include

epoxy coating, nickel plating, or a combination of these methods. With proper coating and strict quality control, Swan Magnets ensures

durability and long-term reliability, fully compliant with international quality standards and customer requirements.

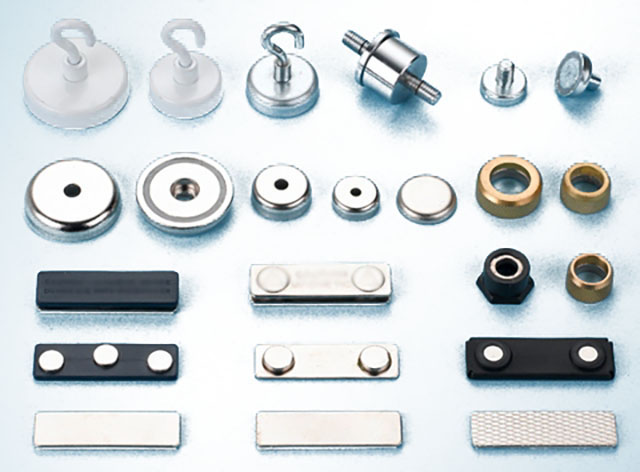

Magnetic assemblies are engineered components that combine permanent magnets with metal or plastic parts to achieve enhanced magnetic

performance and durability. By integrating magnets with housings, shafts, or other mechanical elements, assemblies provide stronger holding

force, improved stability, and extended service life compared to individual magnets.

Our magnetic assemblies are widely used in:

Motors & Generators – for efficient energy conversion and compact design

Sensors & Switches – providing reliable magnetic response and precision

Loudspeakers & Acoustic Devices – ensuring clear and stable sound quality

Magnetic Separation & Filtration – capturing ferrous particles in industrial applications

Customized Solutions – designed according to customer-specific requirements

With advanced production processes including bonding and sintering, as well as multiple surface treatment options (epoxy, nickel, zinc, etc.),

Swan Magnets delivers high-performance magnetic assemblies tailored for demanding applications across various industries.